I’m trying to improve the airflow through my repurposed popcorn popper coffee roaster. At the moment, I need to continuously shake the roaster to get even roasts, but I’d like to just set it and let it run.

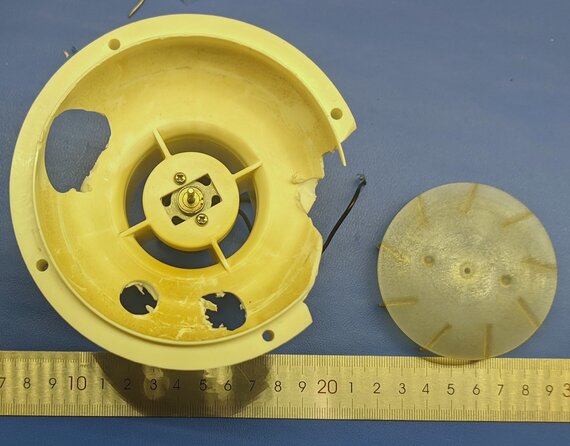

The popcorn popper’s fan is a small impeller on a 12V DC motor. The heating element is used as a voltage divider to supply the motor.

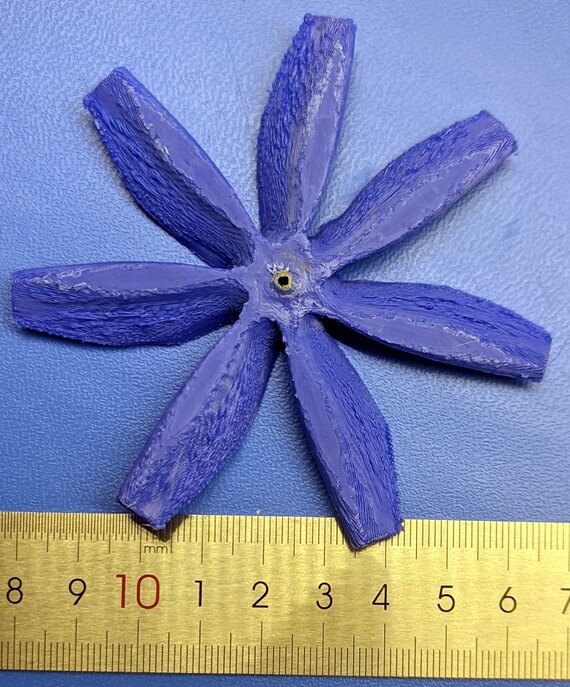

My first attempt was a propeller using the Multipropv6.scad tool and the goe244-il airfoil. This came out far too small, had too fine a pitch, and details too difficult to print.

A second, scaled up attempt came out much better, although the details and pitch were still problematic:

However, once the popper is put back together, it becomes very clear that these axial fans cannot perform with very restricted airflow in the popper.

Alternate fan types

All the Google results are unfortunately useless sales pitches. I did come across a paper from the US Department of Energy which covers the different kinds of fan, as well various design considerations.

I also came across some fascinating experiments with different blower housings and impeller shapes.

Impeller design

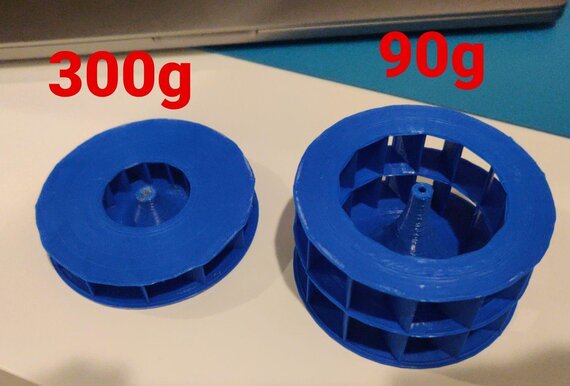

Switching to an impeller fan yielded much better results. One interesting thing I found was that bigger is not always better. With the RS-365SH-2080 motor that I’ve been using, I get much better results with a smaller impeller:

I measured the suction force using a kitchen scale and holding the blower as close as possible to the scale. These impellers are 3d printed, and made using this OpenSCAD script.

I then came across [The Fan Handbook][fanhandbook], which is a great resource and provides design guidance & equations. I haven’t gotten to performing these equations yet, but they seem like a good next step when I pick this project up again.